Have any questions? Tel:

0086-13811860766 |

landy@bambwood.com

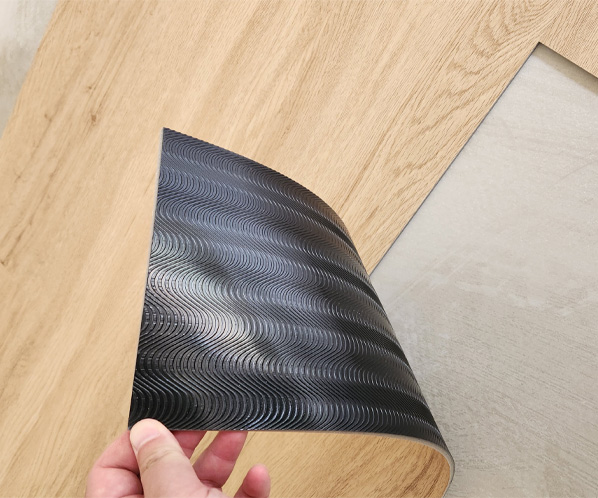

PVC Flooring

We also provide ODM/OEM!

Product Information

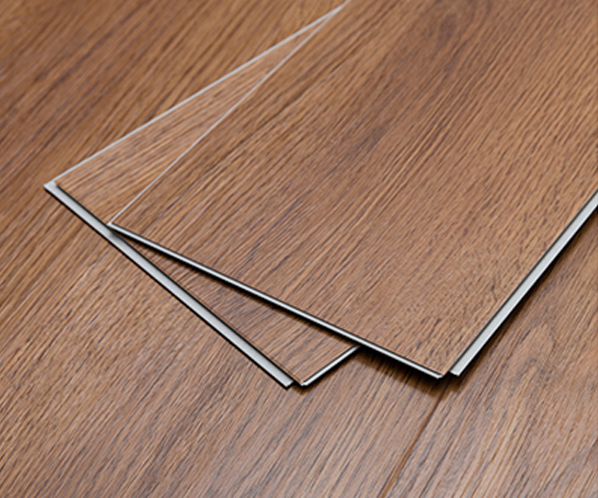

PVC flooring has become a popular choice for modern decoration due to its environmental protection, versatility and economy. Whether it is a residential building that pursues beauty or a commercial space that requires high wear resistance, PVC flooring can provide a flexible and efficient solution.

Description

We are satisfied with the color designs and quality of pvc flooring .Since we ordered, Landy are glad to help us to push the production according to our project schedule. Nice ! Further order will come soon !!

Paramenter

|

Name

|

PVC Flooring/ Lvt Flooring

|

|

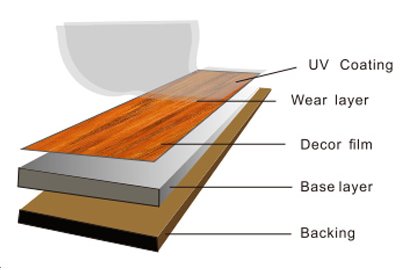

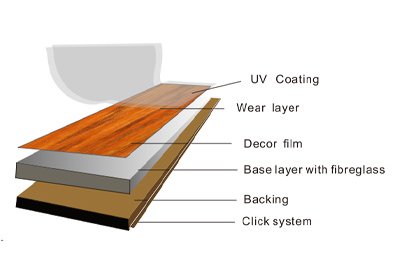

Types of

|

Click Lock;Loose Lay;Dry Back;Glue Down/Adhesive

|

|

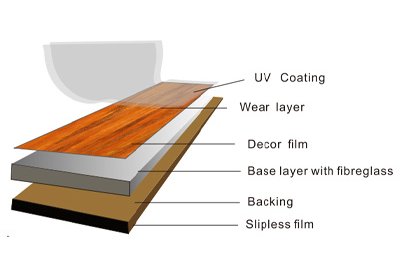

Wear layer

|

0.55mm, 0.7mm;0.07-0.3mm

|

|

Thickness

|

1.5mm 1.8mmm 2.0mm2.5mm3.0mm

|

|

Size

|

184mm*950mm;152.4mm*914.4mm;177.8mm*1219mm;457.2mm*457.2mm

|

|

Material

|

Virgin/Recycled PVC

|

|

Features

|

Waterproof / Anti -slip / Wear-resistance / Fire-resistance / Sound barrier

|

|

Color

|

Customized according to your demands

|

|

Characteristics

|

Standard

|

Control range

|

The measuredresults

|

|

Squareness

|

EN427

|

≤0.15mm

|

0.10mm

|

|

Edge straigheness

|

EN427

|

≤0.15mm

|

0.11mm

|

|

Lock Strength

|

/

|

Thickness (no mat)≥

5.0mm;≥160N/5cm Thickness(no mat)<5.0mm; ≥120N/5cm |

260N/5cm

|

|

Fire Rating-Flame

Spread-CRF |

ASTM E 648

|

Class I(>0.45w/c㎡ )

|

0.99W/c㎡

|

|

Gloss Unit

|

ASTM D523

|

5.5±1º

|

5.9º

|

|

Dimensional stability

(80℃/6h) |

EN434

|

≤0.12%

|

0.08%

|

|

Curling After Exposure

to heat(80℃/6h) |

EN434

|

≤1.2mm

|

0.34mm

|

|

Assembled Gap

|

EN 13329

|

≤0.10mm

|

0.08mm

|

|

Height Difference

(Assembled) |

EN13329

|

≤0.15mm

|

0.10mm

|

|

Wear resistance

|

ASTM D4060

|

Wear Layer Thickness

0.3mm;≥1800cycles Wear Layer Thickness 0.5mm;≥4000cycles Wear Layer Thickness 0.7mm;≥6000cycles |

4200cycles

|

|

Residual indentation

(average) |

ASTM F1914

|

≤8%

|

2.30%

|

|

Castor chair test

|

ISO 4918(EN 425)

|

/

|

OK

|

|

Colour fastness

|

EN20 105-B02

|

degree

|

≥6

|

|

Chemical products resistance

|

EN ISO 26987(EN 423)

|

class I(>0.45w/c㎡ )

|

OK

|

Types

-

Dry Back floor

-

Click floor

-

oose lay

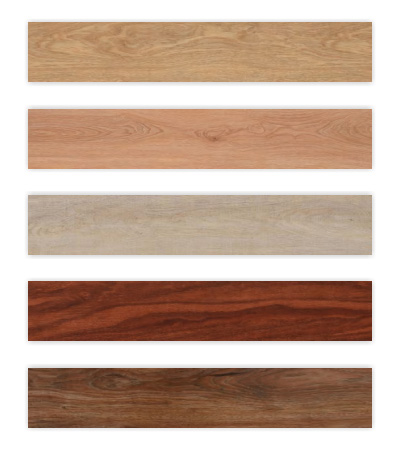

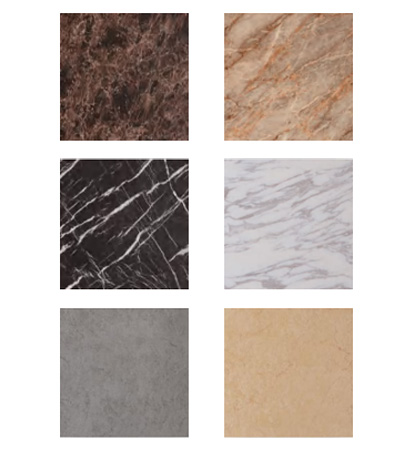

Colors

-

Wood colors

-

Marbie colors

-

Carpet colors

Advantages

-

Fire prevention

-

waterproot

-

Scratch resistant

Application

Leave A Message

TOP

-598-498.jpg)